LED Area Curing System

Introducing the next generation of industrial curing with our LED Area Curing System. Engineered for high performance and efficiency, this system delivers uniform and high-intensity UV light for the rapid curing of large-area adhesives, coatings, and encapsulants. It is the ideal solution for demanding applications across a wide range of industries—from electronics manufacturing and medical device assembly to display production and graphic arts—excelling at critical tasks such as sealing large enclosures, encapsulating circuit boards, and curing coatings on expansive surfaces. With its advanced controller and user-friendly interface, you can precisely manage power and duration to optimize your curing process, ensuring consistent results and maximum productivity. The modular and scalable design of the LED heads makes them perfect for seamless integration into automated production lines and for adapting to a variety of curing geometries and part sizes.

If you have any questions, please contact us to discuss your specific needs.

Technical Specifications

LED Wavelength:

Standard: 365nm, 385nm, 395nm, 405nm

Custom: Other wavelengths available upon request

Light Intensity: Up to 10,000 mW/cm²

Light Uniformity: Better than 90% (application dependent)

Operating Life: > 20,000 hours under normal operating conditions

Cable Length: 2 metres

LED Irradiation Area: See table below

Options: Water cooling option for higher intensity

LED Irradiation Area

Find the perfect fit for your application in the table below, which shows our available standard irradiation areas. We also offer custom sizes and configurations, so feel free to reach out with your specific requirements.

Controller

Display: Intuitive touch-control interface

LED Control Channels: Four LED head channels with independent parameters and operation mode control

Power: Adjustable power settings from 10% to 100%

Timer: Countdown timer settings from 0.1s to 999.9s

Operation Modes:

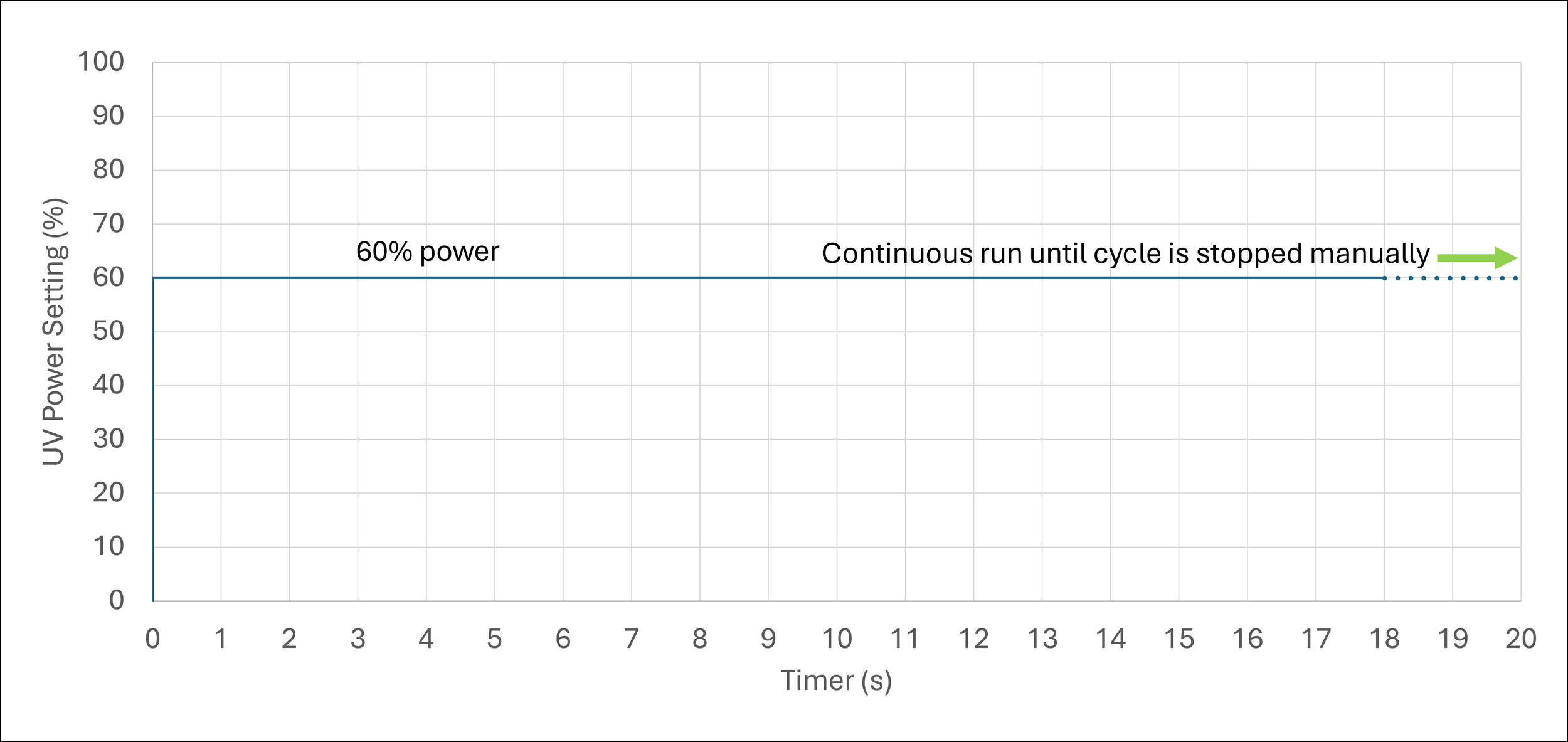

Continuous run at constant power setting

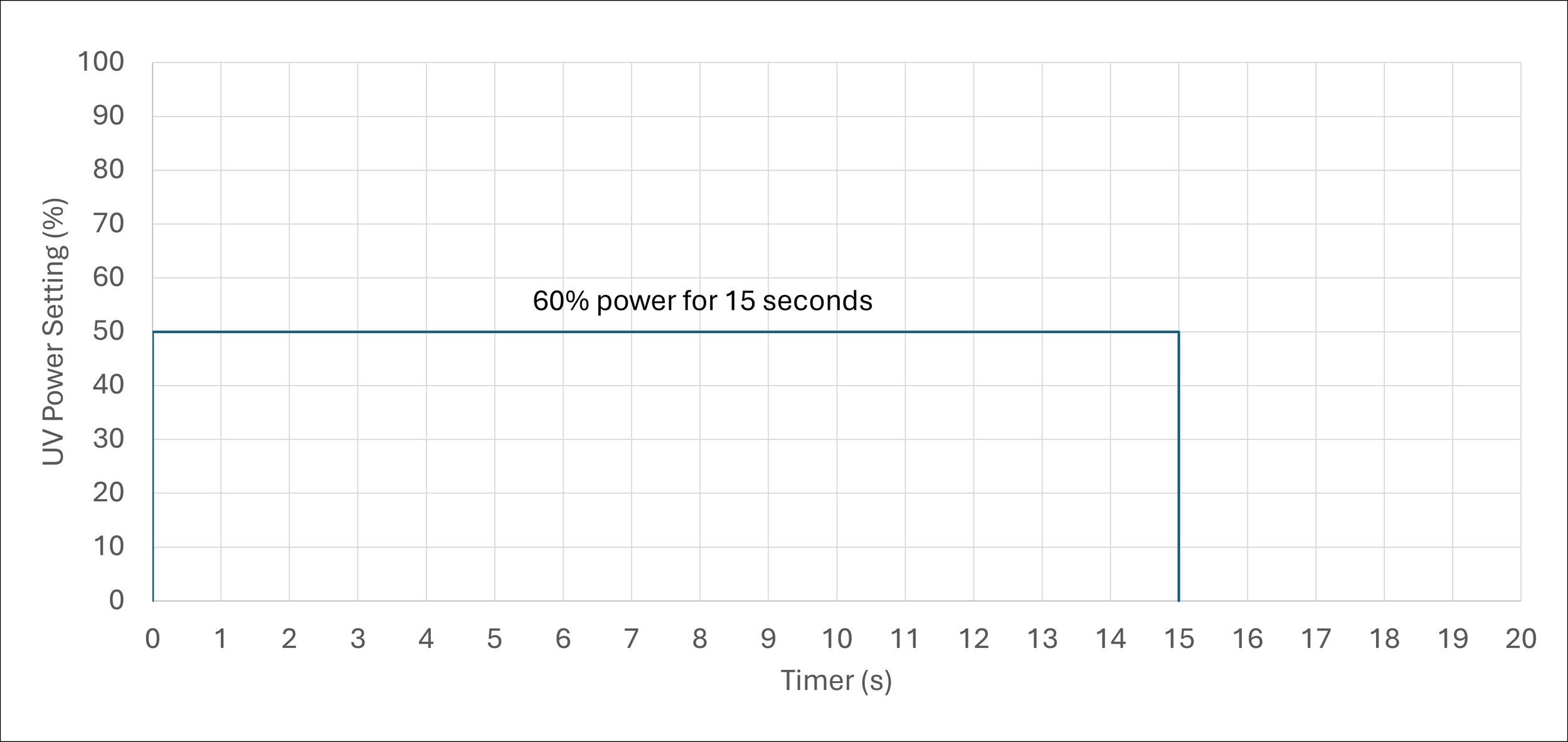

Timer mode at constant power setting

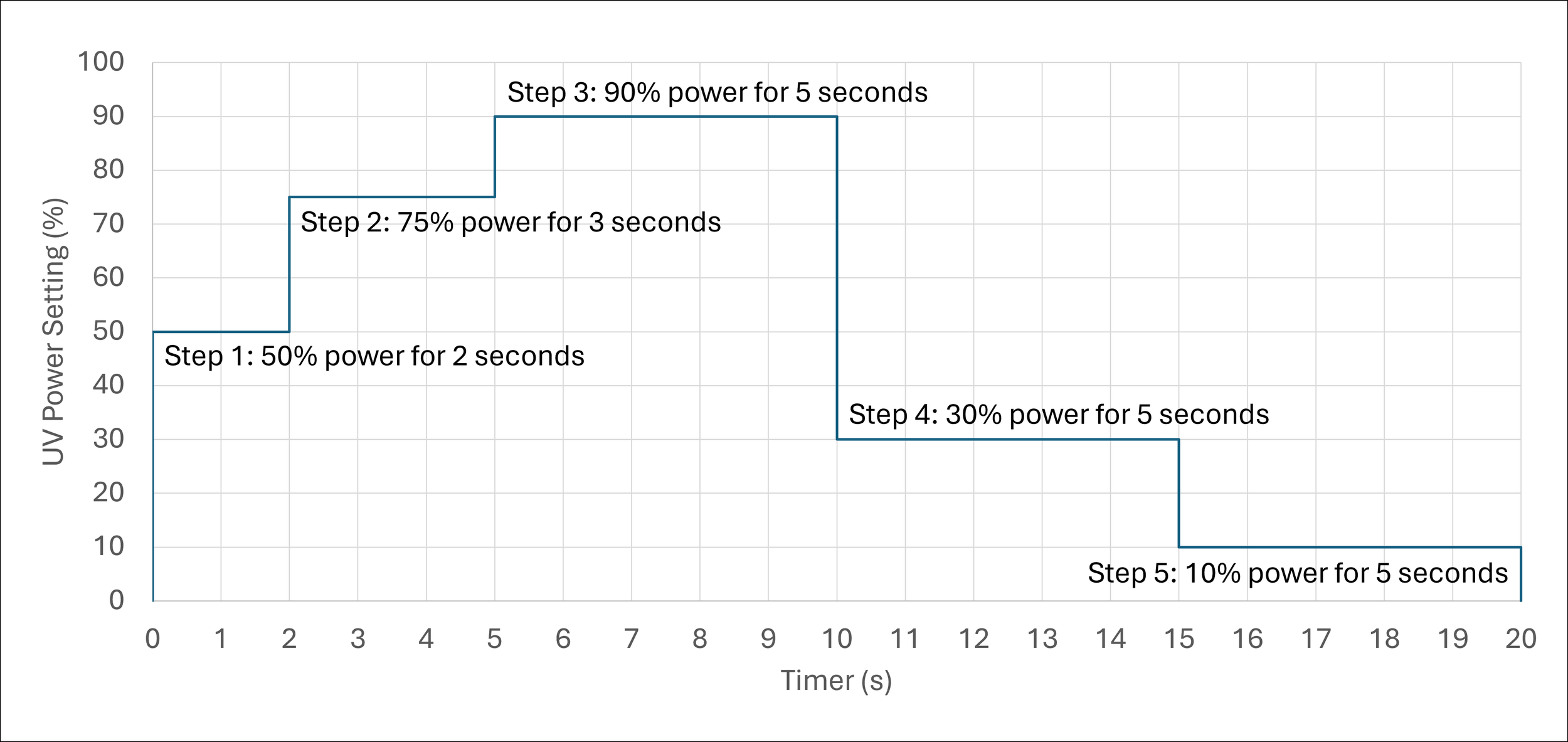

Multi-steps profile, up to 20 steps in 1 cycle

External Controls:

Analog PLC (24V) Input/Output connections

RS232, RS485 communication ports

Footswitch

External safety communication port

Operation Modes

Continuous run

Timer mode

Multi-steps profile

Have questions or need a demo?

We would love to help! Get in touch with our team for more information or to arrange a system demonstration.