Accelerate Your Production with Instant UV Curing

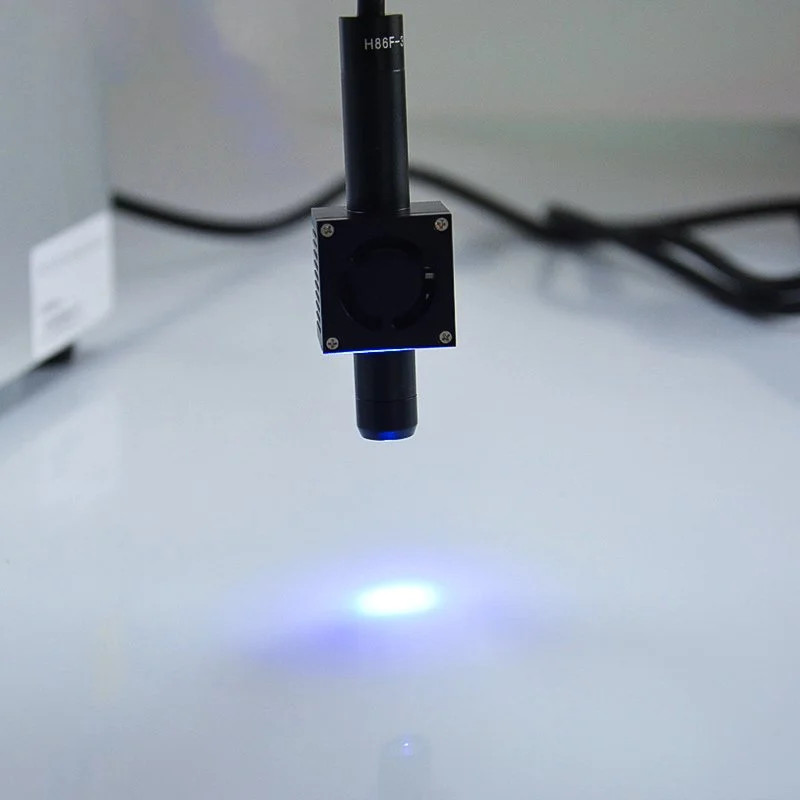

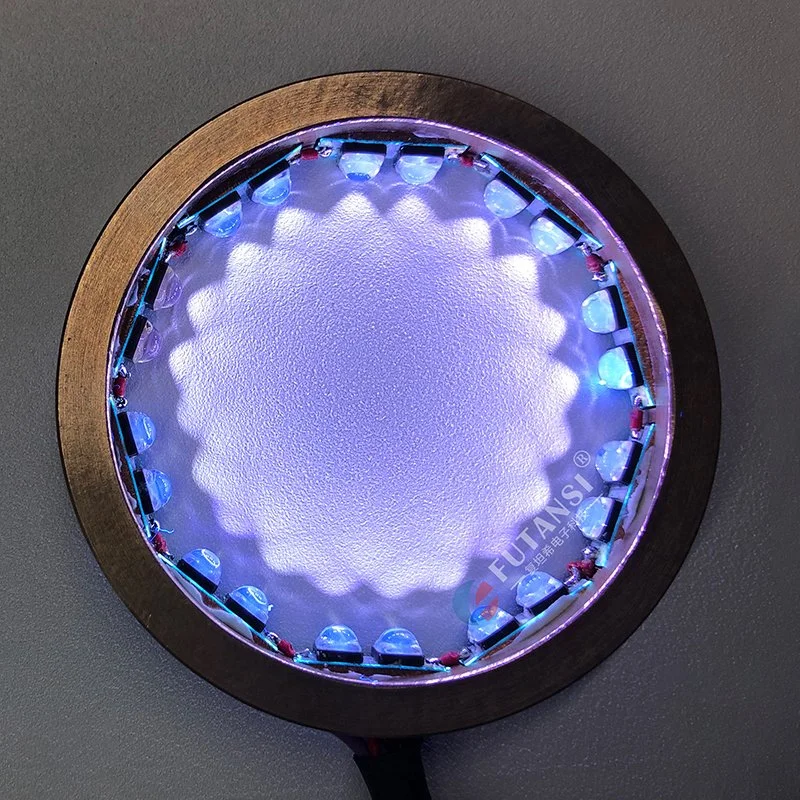

Industrial Ultraviolet LED Curing Systems

With extensive experience in UV curing, we provide a revolution in manufacturing with our UV LED curing systems. Using advanced UV LED technology, our solutions instantly cure adhesives, coatings, inks, and sealants, drastically reducing production time and costs. This fast, precise curing process is ideal for heat-sensitive materials and allows for in-line automation and precise part alignments before curing.

Our versatile systems are trusted in a wide range of industries, including printing, automotive, electronics, medical device assembly, and more. Explore our comprehensive selection of UV LED curing systems, available in various sizes, shapes, and automation capabilities, or contact us to discuss a customised solution for your specific needs.

Applications

Optics:

Curing of optical cement for lens bonding.

Curing of clear monomer resins for micro- or nano-scale lenses. These lenses are essential for advanced optical sensing and light projection in devices such as LiDAR, gesture and facial recognition systems, light carpets, heads-up displays, car headlights, heartbeat sensors, in-ear detection sensors, augmented and virtual reality devices, and many more.

Optical Communication:

Curing of adhesives for bonding waveguides, prisms, diffractive and refractive optics, and mirrors.

Curing of the protective jacket around optical fibres.

Fibre splicing and fixing.

Automotive: Curing of flame retardant coatings during EV battery manufacturing.

Image Sensors: Curing of adhesives for camera lenses and optics used in smartphones, automotive cameras, and endoscopes.

PCB Assembly: Curing of glob top and conformal coating in PCBs.

Smart Cards: Curing of glob top to protect chips from damage.

Plastics: Curing of UV ink and UV lacquer coatings on plastic containers.

Solar Panel Manufacturing: Curing of encapsulation materials for photovoltaic cells.

3D Printing: Curing of resins to finalize 3D printed parts.

Display Technology: Curing of adhesives for glass bonding on displays.

Medical Applications: Curing of adhesives for bonding cannula tips for intracutaneous needles, sealing medical catheters, and connecting plastic tubes.

Research & Development with UV light: Curing of various materials for UV-ageing tests, including assessing the resistance of paints, sunblock lotions, and perfumes against UV light, and studying the degradation of polymer materials.

Futansi Shanghai, China

Futansi is a technology company established in 2010 that specialises in UV LED curing systems. Their headquarters are in Shanghai, with branches located throughout China. The company's vision is to become the leading global supplier of LED UV curing solutions. For more information, visit their website here.

Futansi designs and produces a variety of UV LED systems, including UV curing conveyors, spot curing systems, and chambers. Their products are certified with CE and ISO 9001:2015 management system certifications and are known for their stability and reliability. These products are used in a wide array of fields, such as optical communication, electronic manufacturing, semiconductors, optics, and scientific research.

Adhera is proud to be their distributor in Southeast Asia. Futansi is committed to providing high-quality, safe, and stable products and services to its customers, providing equipment and technical support to over 300 companies globally.