Wafer Tape UV Curing System

Our advanced UV Wafer Tape Curing System delivers uniform, high-intensity UV light to effectively cure UV-sensitive adhesive tapes on wafers, a critical step that significantly reduces the tape's adhesion. This process is essential for achieving a clean and damage-free tape release, which is crucial for subsequent back-end processes like die bonding. With its intuitive touch-screen interface, you can precisely manage power and duration to optimise your curing process. The system's flexible design is compatible with a wide range of wafer sizes and is easily adaptable to your specific production needs. Equipped with a comprehensive suite of safety features and a long-life LED light source, this system ensures consistent results, maximum productivity, and a safe working environment for your operators.

If you have any questions, please contact us to discuss your specific needs.

Technical Specifications

LED Wavelength: 365nm, other wavelengths upon request

Light Intensity: Up to 400 mW/cm²

Power: Adjustable power settings from 10% to 100%

Timer: Countdown timer settings from 0.1s to 999.9s

Wafer loading and unloading: Manual

Wafer Size Compatibility: 4”, 6”, 8”, 10” and 12” interchangeable

Operating Life: > 20,000 hours under normal operating conditions

Controls: Integrated intuitive touch-screen controls or a separate LED controller unit

Safety Features: Complete UV-blocking enclosure, chamber door safety cut-off, traffic light beacon with alarm (optional), emergency stop switch (optional)

Operation Modes:

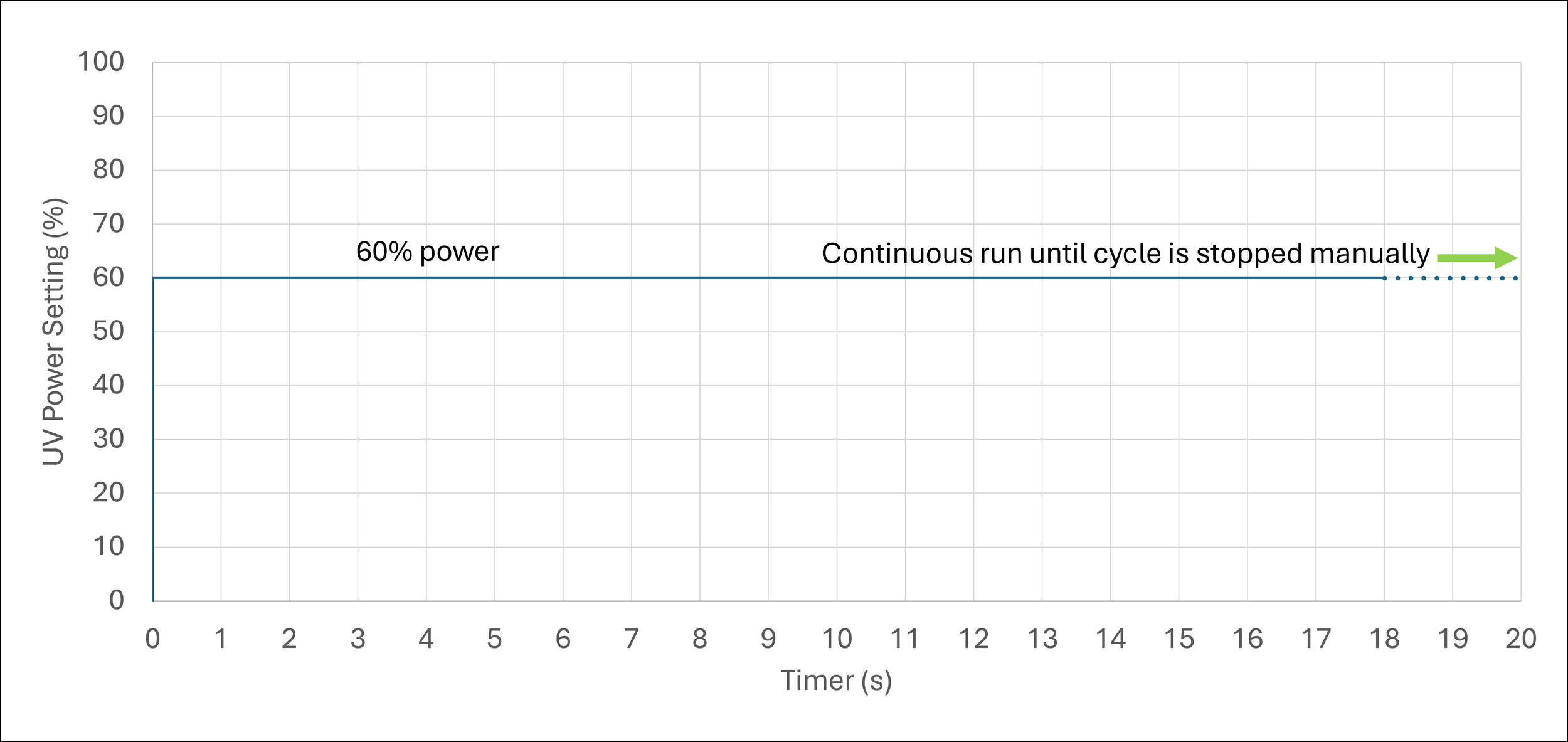

Continuous run at constant power setting

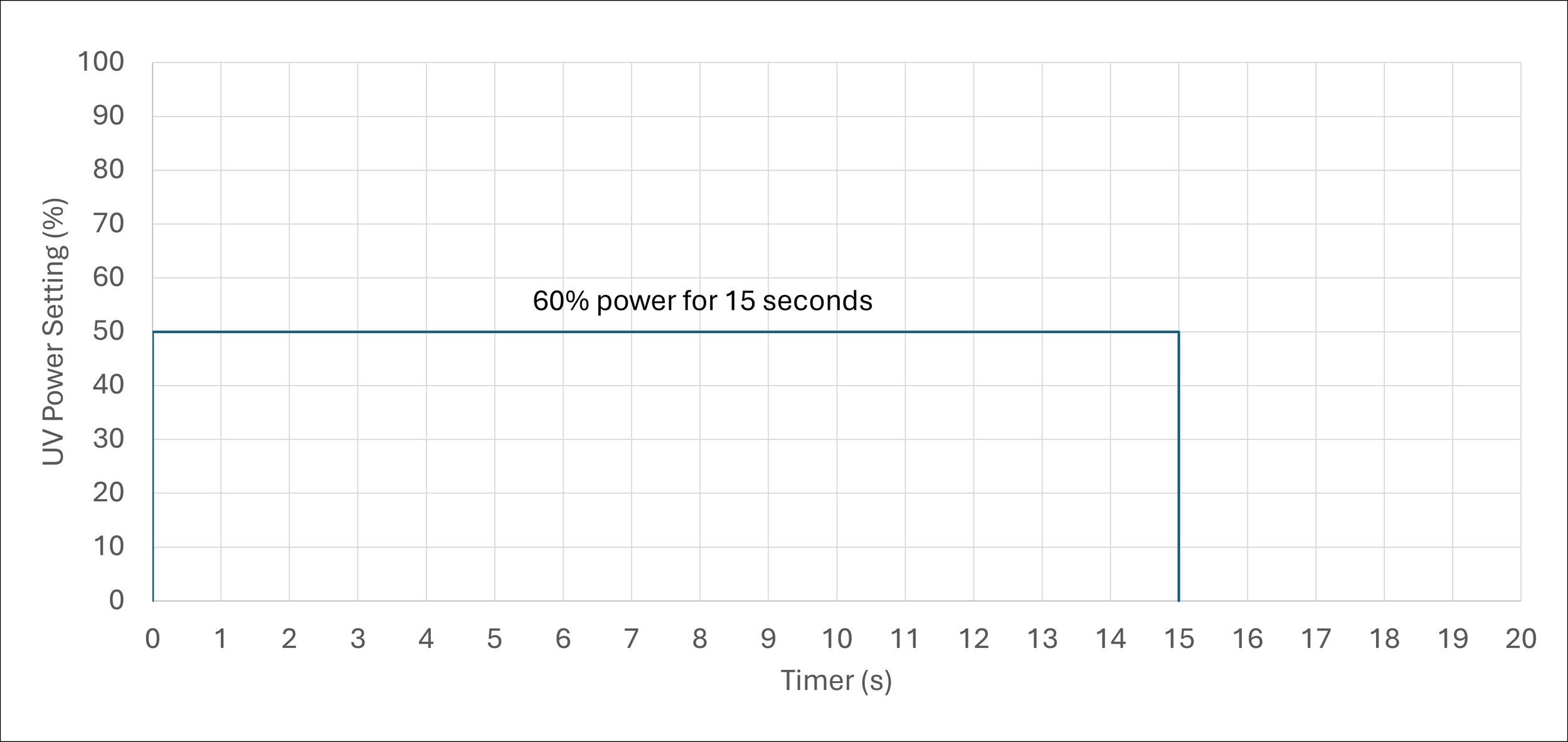

Timer mode at constant power setting

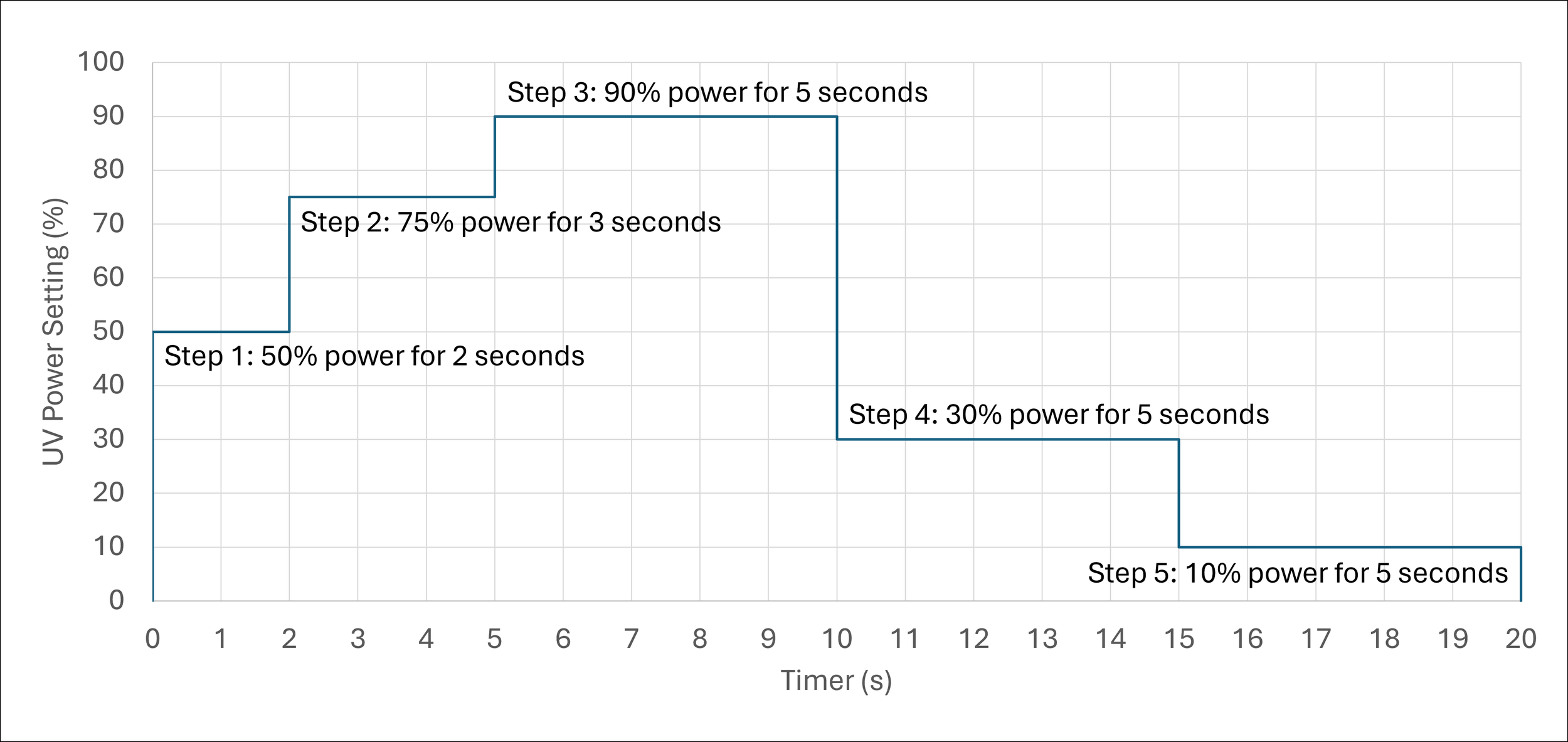

Multi-steps profile, up to 20 steps in 1 cycle

Options: Inert (Nitrogen) gas environment

Bench-top wafer tape UV curing System

Compatible fixture for 4” to 12” common wafer dicing rings

Operation Modes

Continuous run

Timer mode

Multi-steps profile

Have questions or need a demo?

We would love to help! Get in touch with our team for more information or to arrange a system demonstration.