Encapsulants, Potting and Underfill Adhesives

Modern microelectronics demand more than just a physical bond. They require materials that can handle increased power, dissipate heat efficiently, and perform reliably under harsh conditions. Our comprehensive portfolio of adhesives and encapsulants is engineered to meet these challenges, offering a wide range of solutions for protecting sensitive electronic components. From specialised underfills that provide crucial protection against mechanical and thermal stress to glob top and dam & fill encapsulants that protect bare dies and other sensitive components, our products ensure the long-term durability of your assemblies. We also offer potting and casting resins that provide a solid, insulating barrier against environmental stresses like moisture, chemicals, and vibration. Our materials are designed to enhance the performance and reliability of your devices, ensuring you have the right solution for every application.

If you have any questions, please contact us to discuss your specific needs.

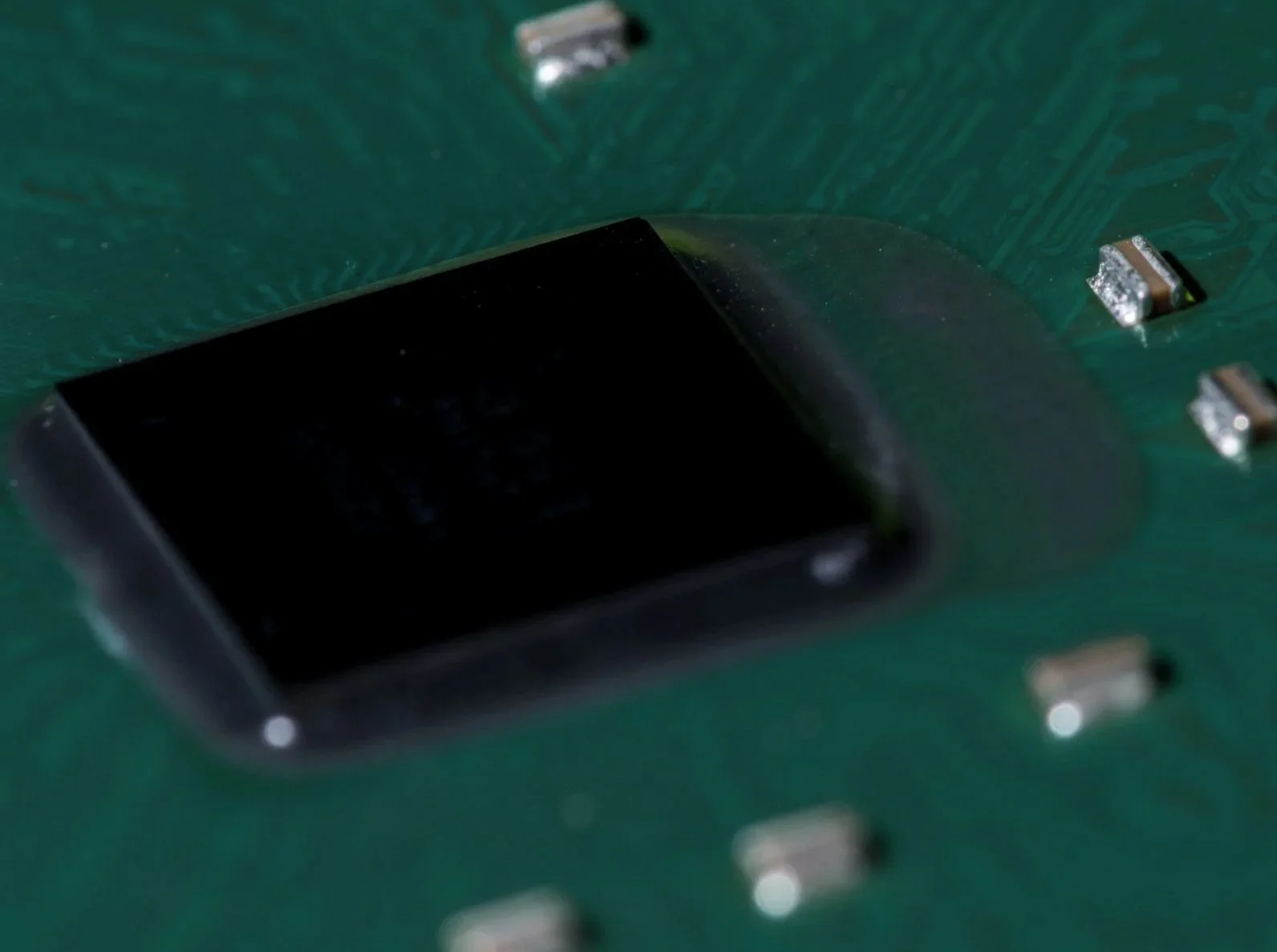

Encapsulation, Glob Top, Dam and Fill

Glob Top and Dam & Fill encapsulants are a type of material used to protect sensitive electronic components from harsh environments. These epoxy-based resins provide reliable protection for bare silicon dies, crystal oscillators, and other components in micro-electronic assemblies. They are an effective solution in demanding applications that require resistance to thermal cycling and humidity.

Glob Top encapsulants are typically used for smaller chips, while Dam & Fill encapsulants are used for larger dies. Dam & Fill materials are also optimised for a co-cure process to minimise production time.

Key Properties

Formulation: 1-component epoxy-based adhesives

Applying Methods: Dispensing and jetting

Curing:

Thermal curing 150°C for 2 hours or 165°C for 1 hour

UV-A Curing 120 mW/cm² for 30 seconds for a 500µm thick layer

Work Life: Ranges from 60 minutes to 48 hours, which allows for flexibility in production processes.

Glass Transition Temperature (Tg): Up to 250°C

Coefficient of Thermal Expansion (CTE): As low as 18 ppm/K

Application-Specific Options:

UV curing options available for applications on temperature-sensitive substrates where a quick, low-heat curing process is required.

Soft formulations ideal for use with flexible substrates.

Please contact us here to discuss the specific products and the possibility of a customised development.

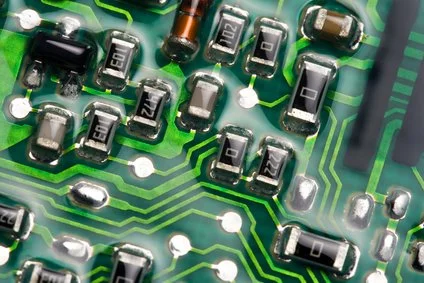

Underfill, Corner and Edge Bonding

Underfill and cornerbond encapsulants are epoxy-based materials designed to protect electronic components like BGA, CSP, and Flip Chips from mechanical and thermal stress. Underfills fill the gap between the component and the circuit board, providing protection against shock, drop, vibration, and thermal cycling. Cornerbonds and edgebonds offer targeted adhesive solutions for specific areas, enhancing the overall durability of the assembly.

Key Properties

Formulation: 1-component epoxy-based underfill, B-stage underfill

Applying Methods: Dispensing and jetting

Curing:

Thermal curing as fast as 3 mins at 150°C

Low temperature curing at 80°C for 120 mins

B-stage underfills tacked at 90°C for 2 hours and fully cured at 150°C for 3 hours

Work Life: Ranges from 12 hours to more than a week, which allows for flexibility in production processes.

Glass Transition Temperature (Tg): Up to 250°C

Coefficient of Thermal Expansion (CTE): As low as 14 ppm/K

Application-Specific Options:

Zero-gap underfills with excellent capillary flow are available for solder bump standoffs as small as 5µm.

High-temperature-resistant underfills with Tg of up to 250°C.

B-stage underfills are available.

Highly thermally conductive underfills with thermal conductivity of 0.9 W/m·K.

Certain materials can be co-cured during a solder reflow process.

Low-outgassing products meeting NASA emission standards.

Please contact us here to discuss the specific products and the possibility of a customised development.

Potting and Casting

Potting and casting resins are a type of liquid thermosetting polymer that is applied to electronic or electrical components and devices. Once cured, they become solid, durable materials that provide an insulating and protective barrier against environmental stresses such as moisture, chemicals, vibration, and thermal shock.

Key Properties

Formulation: 2-component epoxy-based and silicone-based resins, B-stage potting resins

Applying Methods: Dispensing and pouring

Curing

Room temperature curing for 24 hours after mixing

Accelerated curing at temperature as low as 65°C for 1 hour after mixing

B-stage curing 90°C for 2 hours followed by 150°C for 3 hours

Work Life: Ranges from 45 mins to 24 hours

Application-Specific Options:

Low-shrinkage formulations to prevent stress on delicate components during curing.

Highly thermally conductive materials, with thermal conductivity up to 1.8 W/m·K, to effectively dissipate heat from electronics.

Crystal-clear formulations ideal for potting and encapsulating LEDs and other optical components.

Flame retardant materials that meet UL94-V0 safety standards.

Specialised products formulated to withstand a wide range of extreme temperatures, from cryogenic (-200°C) to continuous high-heat environments (up to 250°C).

Materials safe for biomedical and food contact applications, meeting standards such as BS6920 for drinking water and FDA regulations for indirect food contact.

Products with adjustable flexibility and hardness, where properties can be fine-tuned by changing the mixing ratio of the two components.

Please contact us here to discuss the specific products and the possibility of a customised development.