Electrically and Thermally Conductive Materials

Advanced microelectronics demand more than just a physical bond. They require materials that can handle increased power, dissipate heat efficiently, and perform reliably under harsh conditions. Our portfolio of electrically and thermally conductive materials is engineered to meet these challenges head-on, offering a comprehensive range of solutions for your specific manufacturing needs. From isotropic conductive adhesives that replace traditional solder to high-performance sintering materials for power electronics, our products are designed to enhance the performance and reliability of your devices. We also offer specialised materials like anisotropic conductive adhesives, thermally conductive dielectric adhesives, thermal gap fillers, thermal greases, and functional inks, ensuring you have the right solution for every application.

If you have any questions, please contact us to discuss your specific needs.

Electrically Conductive Adhesives (Isotropic)

Isotropic conductive adhesives are a versatile class of materials designed to create electrical connections in micro-electronic assemblies where conductivity is required in all three dimensions. This functionality makes them a suitable alternative to solder pastes, especially in applications that demand increased flexibility and durability to withstand severe thermal cycling. The adhesives are also well-suited for bonding micro-electronic components to temperature-sensitive substrates, such as flexible circuits, and are compatible with a range of application methods, including dispensing, screen printing, and jetting.

Key Properties

Formulation: 1- and 2-component adhesives

Applying Methods: Dispensing, jetting, stencil printing, screen printing

Curing:

1-component: As fast as 5 mins at elevated temperatures > 150°C

2-component: 24 hours at room temperature or faster at elevated temperatures

Volume Resistivity: Typically less than 5×10−4 Ohm-cm, ensuring efficient electrical conductivity.

Work Life: Work life ranges from 45 minutes to 5 days, which accommodates different production line speeds and processes.

Application-Specific Options:

Low-Temperature Cure:

80°C for 1-component material

Room temperature for 2-component

Low outgassing: Meeting NASA or ESA outgassing standards

Flexibility: To overcome coefficient of thermal expansion (CTE) mismatch

Variety of viscosity and thixotropic index for different application methods.

Please contact us here to discuss the specific products and the possibility of a customised development.

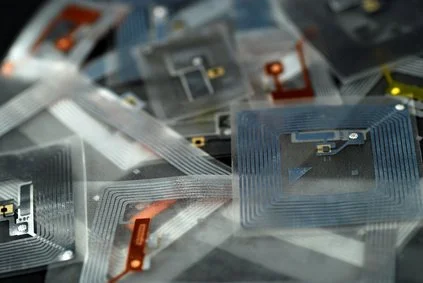

Electrically Conductive Adhesives (Anisotropic)

Anisotropic conductive adhesives are a specialised class of materials designed to create electrical connections in micro-electronic assemblies where conductivity is limited to the vertical (Z-direction). This functionality makes them particularly well-suited for applications involving fine pitch connections and for technologies such as flip-chip, where traditional solder methods are not feasible. The product range is designed for compatibility with a variety of application methods, including dispensing, screen printing, and jetting, and features formulations with both ultra-fast spot-cure chemistries and slower curing rates.

Key Properties

Formulation: 1-component adhesives only

Applying Methods: Dispensing, jetting, stencil printing

Curing: As fast as < 1min

Work Life: Work life ranges from 12 hours to 5 days, which accommodates different production line speeds and processes.

Application-Specific Options:

Environment-safe formulation: The adhesives utilise environmentally friendly fillers and do not contain nickel-based filler technology.

Peformance: Excellent adhesion strength and high corrosion resistance

Flexibility coefficient of thermal expansion (CTE) mismatch

Variety of viscosity and thixotropic index for different application methods.

Please contact us here to discuss the specific products and the possibility of a customised development.

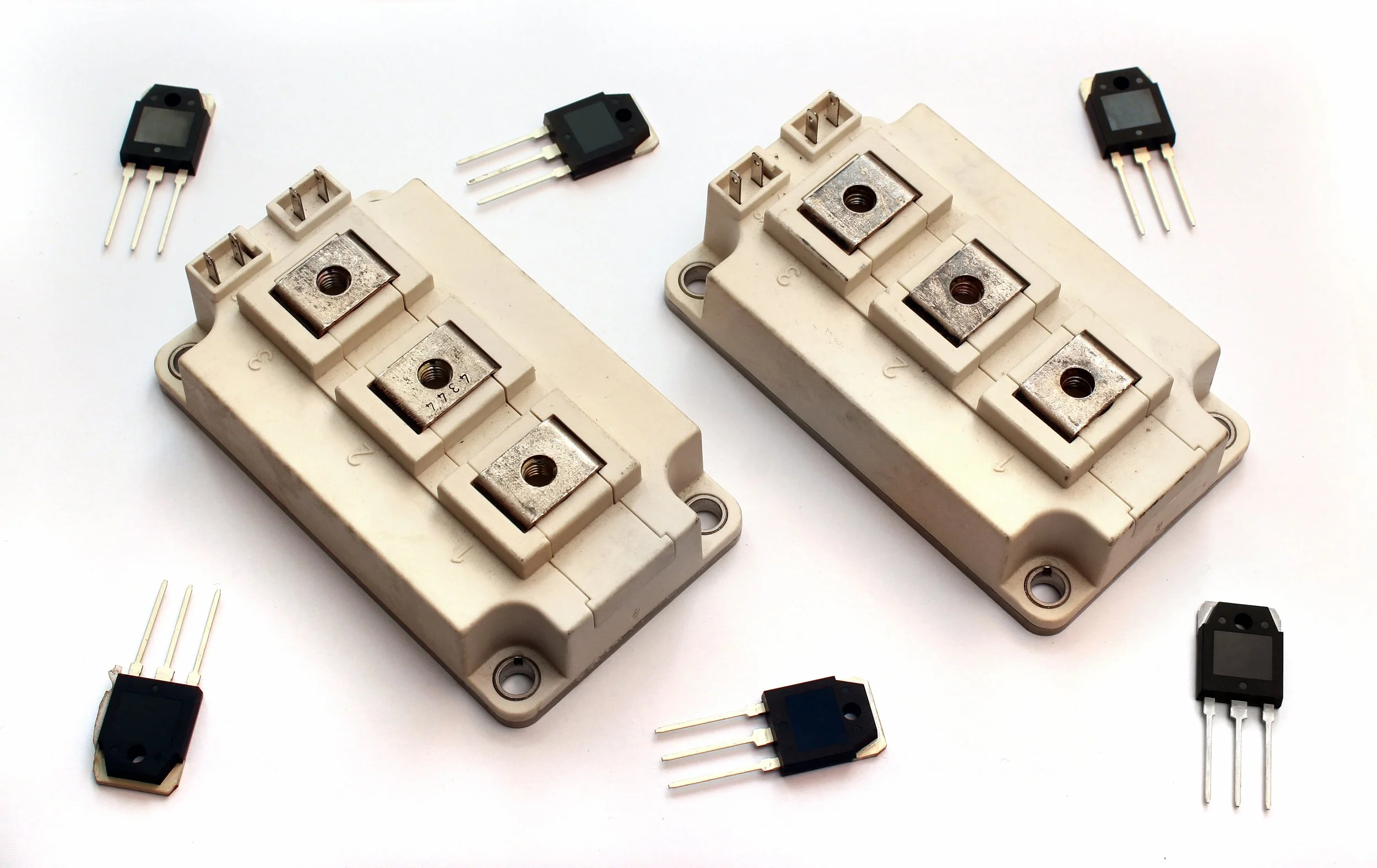

Sintering Materials

Sintering materials, which include thermoset hybrid-sintering epoxy based adhesives and silver-based pastes, are used for high-power die attach applications. These materials are valued for their combination of high temperature resistance and best-in-class thermal and electrical conductivity. They are well-suited for applications such as power semiconductors, LEDs, automotive EV power modules, and RF devices. Despite their high filler loading, these materials have a relatively low viscosity, which makes them well-suited for easy application like dispensing and stamping.

Key Properties

Formulation: Silver and copper sintering pastes, and hybrid-sintering epoxy based adhesives.

Applying Methods: Dispensing, stamping, stencil printing

Sintering Methods:

Pressure-assisted: Drying at 200°C for 10 mins and sintering at 250°C for 5 mins

Pressure-less: 200°C for 1 hour

Hybrid-sintering epoxy based adhesives: 120°C for 15 mins and ramp up to 200°C in 15 mins

Volume Resistivity:

Sintering Pastes: As low as 4 x 10-6 Ohm.cm

Hybrid-sintering epoxy based adhesives: As low as 3.8 x 10-6 Ohm.cm

Thermal Conductivity:

Sintering Pastes: >200 W/m.K

Hybrid-sintering epoxy based adhesives: >60 W/m.K

Work Life: Up to 24 hours

Application-Specific Options:

Variety of viscosity for different application methods.

Choice of silver or copper-based materials.

Versions with improved electrical conductivity.

Options specifically designed for high-speed, fine dot dispensing.

Please contact us here to discuss the specific products and the possibility of a customised development.

Thermally Conductive Adhesives (Dielectric)

Electronic devices are becoming smaller, lighter, and more powerful, which has increased the demand for effective thermal dissipation materials. Thermally conductive dielectric adhesives are designed to assist in heat dissipation while maintaining electrical insulation. These materials are integrated with thermally conductive fillers and are ideal for applications that require dissipating heat away from temperature-sensitive components through very thin bond lines.

Key Properties

Formulation: 1- and 2-component adhesives.

Applying Methods: Dispensing, stamping, stencil printing.

Curing:

1-component: As fast as 1-2 minutes at 150°C, or 30 minutes at 80°C.

2-component: As fast as 1 minute at 80°C, or 24 hours at 25°C.

Thermal Conductivity: Ranges from 0.7 to 2.3 W/m.K.

Work Life: Varies from as little as 4 minutes for fast-cure versions to over 5 days for others.

Application-Specific Options:

Variety of viscosities for different application methods, including non-sagging (high aspect ratio) options.

Non-abrasive fillers for sensitive components.

Low outgassing formulations that are ESA-approved.

Flexibile materials to overcome coefficient of thermal expansion (CTE) mismatch.

Economical and fast-cure options available.

Specific mix-ratios for 2-component adhesives.

Please contact us here to discuss the specific products and the possibility of a customised development.

Thermal Gap Fillers

Thermal gap-filler materials are a key component in modern electronics, especially for high-reliability automotive and industrial applications that face harsh environments. Unlike traditional thermal pads, liquid gap fillers provide excellent thermal dissipation, vibration resistance, and high adhesion. They are also silicone-free, which helps prevent contamination of sensitive electronic parts.

Key Properties

Formulation: Liquid, 2-component gap-filler materials.

Applying Methods: Dispensing

Curing: Medium to fast cure at low temperatures.

Thermal Conductivity: Ranges from 0.8 to 1.3 W/m.K.

Application-Specific Options:

Options for medium, high, and very high viscosity, including non-sagging (high aspect ratio) formulations.

Several products are very flexible, making them suitable for "low stress applications”.

Solvent-free and epoxy-based chemistry

Available in various shades of dark orange and red.

Please contact us here to discuss the specific products and the possibility of a customised development.

Thermal Grease

Thermal greases are thermally conductive pastes that serve as a thermal interface material between a heat source, like a semiconductor, and a heat sink. Their primary function is to eliminate insulating air gaps, maximising heat transfer and improving the cooling of the heat-generating device. Unlike thermally conductive adhesives, thermal greases offer no mechanical bond and require a mechanical fixation mechanism, such as screws, to apply pressure and ensure proper spreading.

In a key differentiator from many traditional suppliers, our thermal greases are non-silicone based, which eliminates the risk of silicone contamination in sensitive applications, such as in semiconductor or automotive assemblies.

Key Properties

Formulation: Silicone-free thermal wax or silicone-based greases.

Applying Methods: Dispensing, screen printing

Thermal Conductivity: Ranges from 1.4 to 6.1 W/m.K.

Application-Specific Options:

A wide range of viscosities from 45,000 to 5,000,000 mPa.s, including non-sagging (high aspect ratio) options.

Options with the highest thermal conductivity available (up to 6.1 W/m.K).

Certain formulations are designed for low outgassing, making them suitable for specialised applications.

Lower-cost, general-use versions are available.

Non-silicone and silicone-based formulations are offered to suit different application requirements and mitigate the risk of silicone contamination.

Please contact us here to discuss the specific products and the possibility of a customised development.

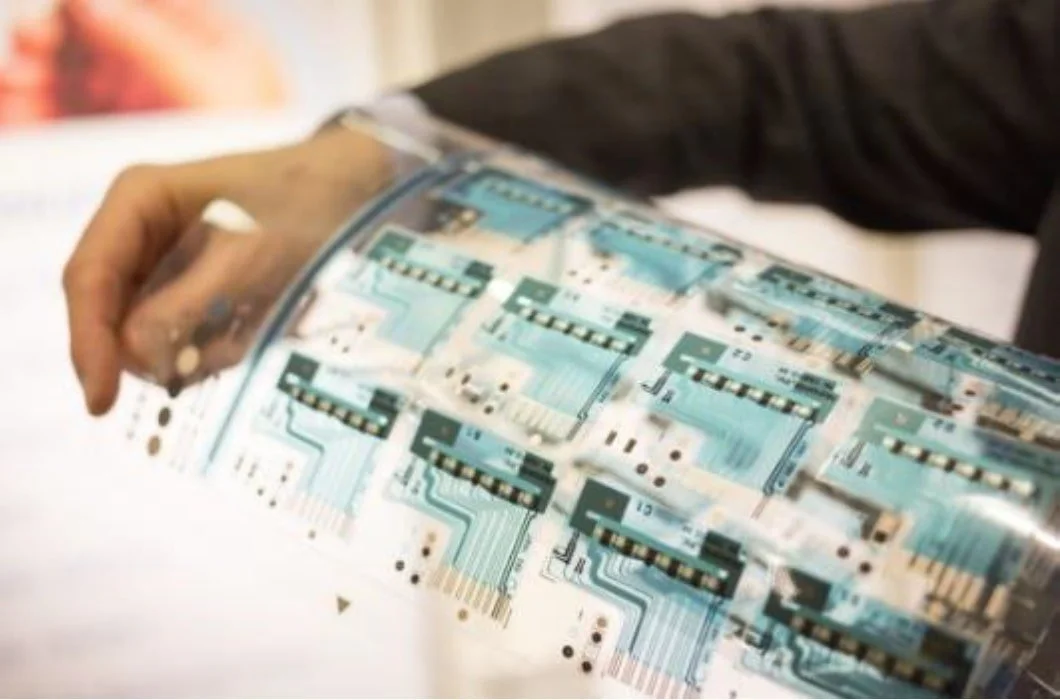

Functional Inks

Functional inks are solutions designed for a wide range of printed electronics applications in markets such as IoT, consumer electronics, medical, automotive, and building. As electronic devices become smaller and more complex, there is an increasing demand for inks that can achieve fine line printing while maintaining robust conductive and other functional properties. They are especially useful for printing electronics on flexible and thin films. The portfolio of these inks is formulated to meet the demands of advanced applications and can be used with various printing methods.

Key Properties

Formulation: Electrically conductive and dielectric inks.

Applying Methods: Screen printing and inkjet printing.

Curing: Cured for 15 minutes at 120°C, with some being UV-curable.

Sheet Resistivity: As low as 0.025 Ohm/sq/25μm.

Dielectric Ink for bridging coating in printed electronics

Storage: 12 months.

Application-Specific Options:

Variety of viscosities for different application methods (11,000 to 36,000 mPa.s).

Options with excellent elongation properties.

Versions that are thermoformable (can be heated and molded into different 3D shapes without crin electrical conductivity.

Economical formulations available.

Choice of colors including silver, black, light brown, and gray.

Please contact us here to discuss the specific products and the possibility of a customised development.