LED Spot Curing System

Introducing the next generation of industrial curing with our LED Spot Curing System. Engineered for superior performance, this system delivers instant and highly stable UV intensity for the rapid curing of adhesives, coatings, and sealants. It is the ideal solution for demanding applications across a wide range of industries, including optical sensors, optical communication, laser communication, medical device assembly, and printing. Our system excels at critical tasks such as optical fibre alignment bonding, optics active alignment bonding, and curing small parts and components. With its multi-channel controller and user-friendly interface, you can precisely manage power and duration to optimize your curing process, ensuring consistent results and maximum productivity. The compact and lightweight design of the LED heads makes them perfect for seamless integration into automated production lines and for curing in even the most confined spaces.

If you have any questions, please contact us to discuss your specific needs.

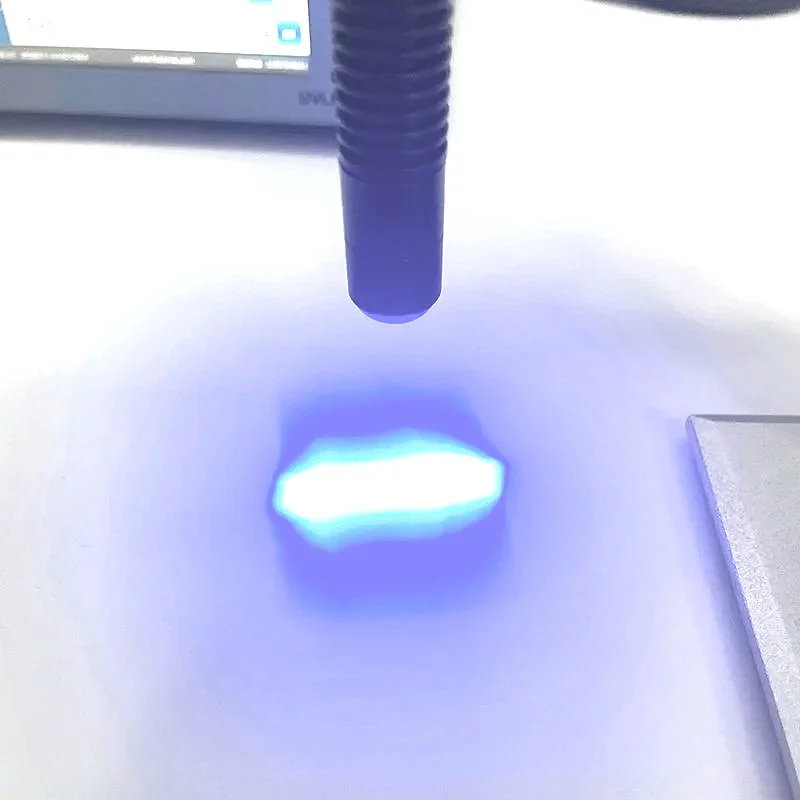

High Intensity LED Heads

Wavelength:

Standard: 365nm, 385nm, 395nm, 405nm

Custom: Other wavelengths available upon request

Light Intensity:

Up to 10,000 mW/cm²

Operating Life:

> 20,000 hours under normal operating conditions

Cable Length:

2 to 5 metres, extension cables available

Head Options:

Short (56mm), Medium (86mm) or Long (106mm) head

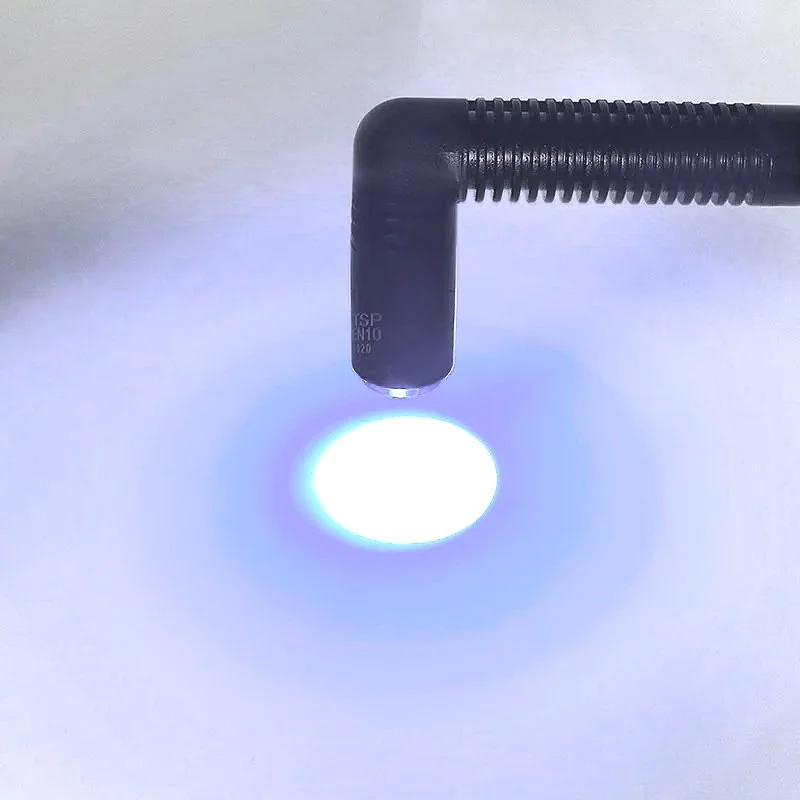

L-shaped head

90° irradiation angle for confined spaces

Air cooling module

Optics:

Irradiation Area (Round) - 1.5mm, 3mm, 4mm, 5mm, 6mm, 7mm, 8mm, 10mm, 12mm, 16mm, 20mm

Irradiation Area (Rectangular) - 3mm x 12mm, 4mm x 18mm, 5mm x 20mm, ideal for curing adhesive bond lines from the side.

Air cooling module for active temperature regulation of the LED head

56mm, 86mm and 106mm LED head length

90° irradiation LED head for curing in confined spaces

Rectangular irradiation area for horizontal bond line curing

L-shaped LED Head

Controller

Display: Intuitive touch-control interface

LED Control Channels: Four LED head channels with independent parameters and operation mode control

Power: Adjustable power settings from 10% to 100%

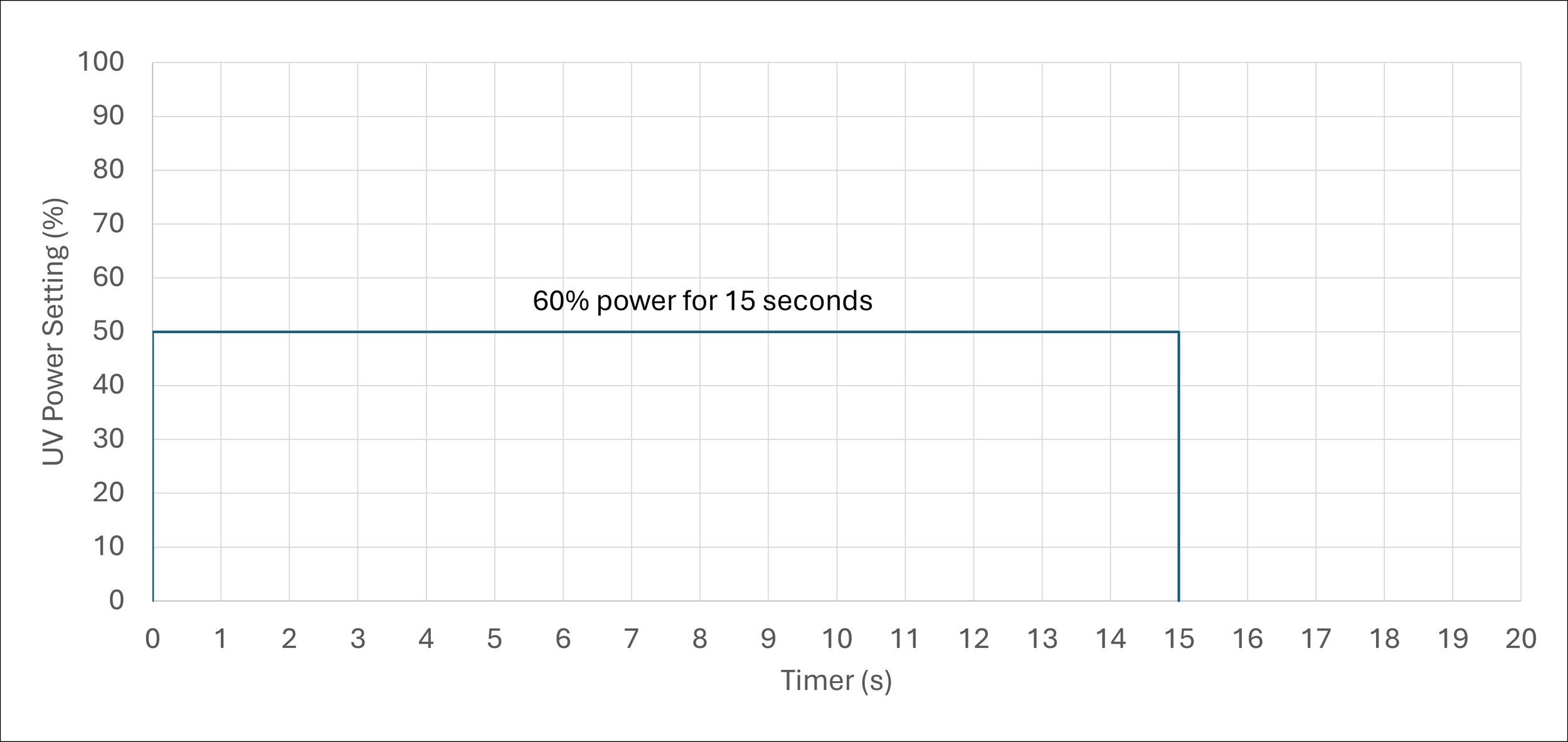

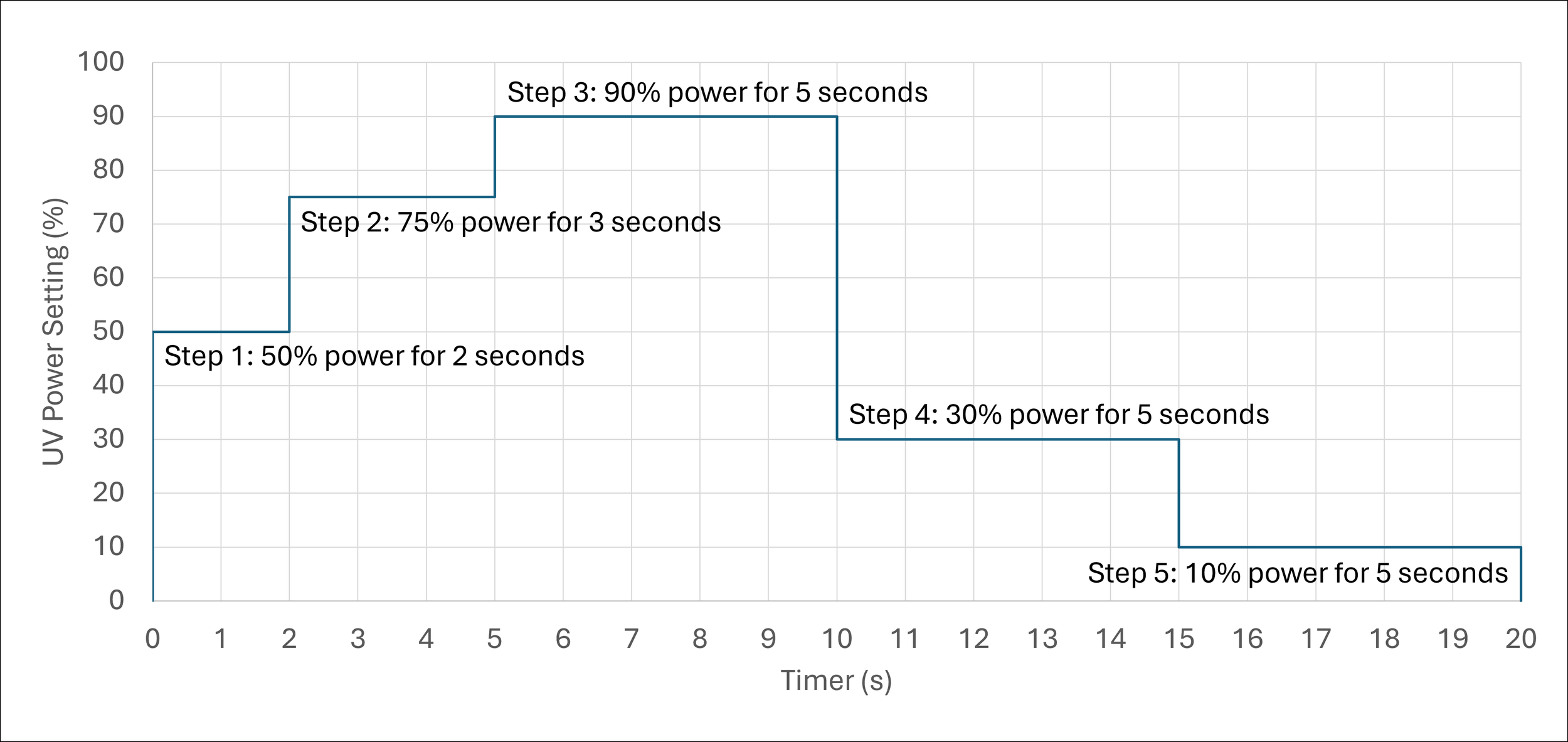

Timer: Countdown timer settings from 0.1s to 999.9s

Operation Modes:

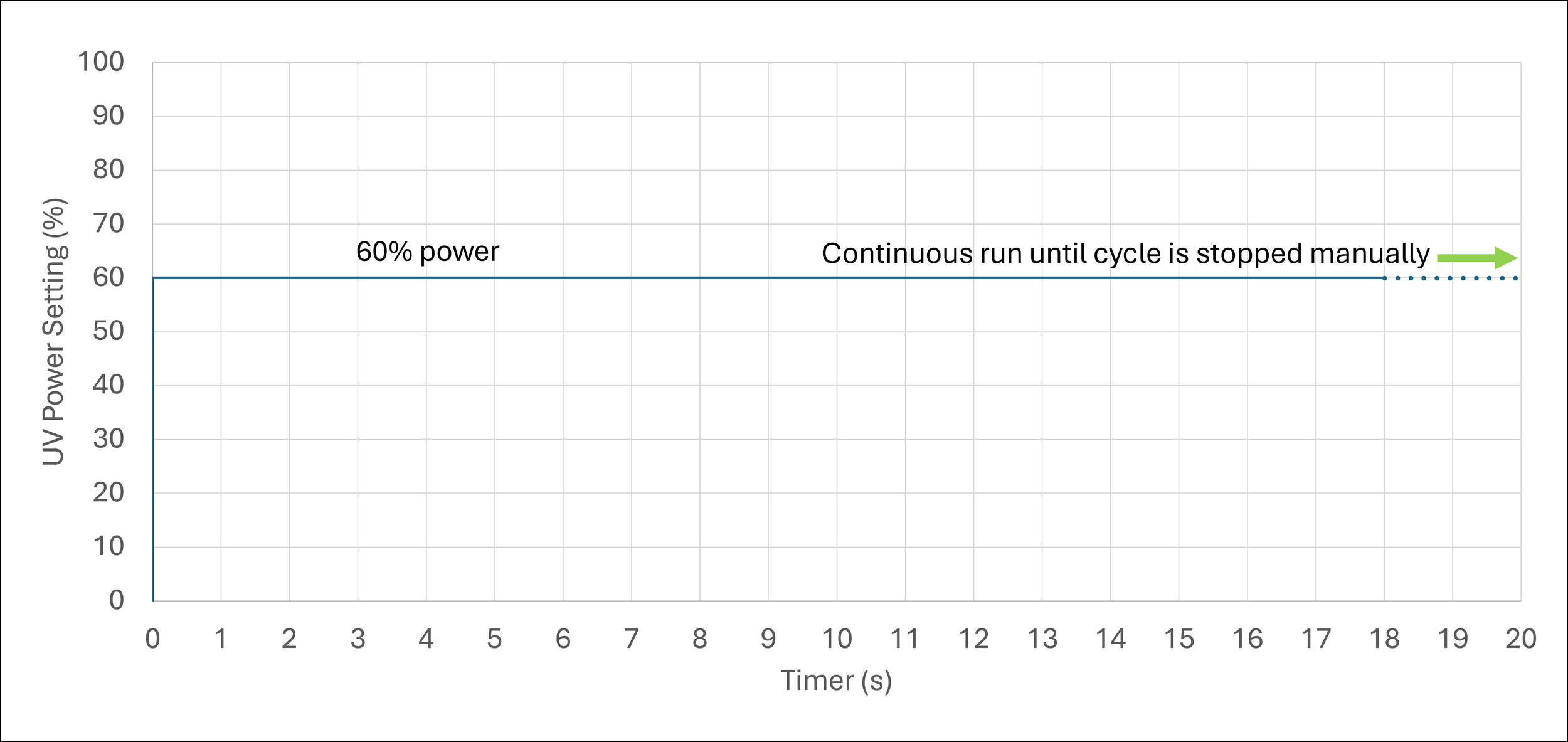

Continuous run at constant power setting

Timer mode at constant power setting

Multi-steps profile, up to 20 steps in 1 cycle

External Controls:

Analog PLC (24V) Input/Output connections

RS232, RS485 communication ports

Footswitch

External safety communication port

Operation Modes

Continuous run

Timer mode

Multi-steps profile

Have questions or need a demo?

We would love to help! Get in touch with our team for more information or to arrange a system demonstration.