UV Curing Chamber

The UV Curing Chamber is a simple, cost-effective solution for reliable batch processing across a wide range of industrial and scientific needs. Designed with operator safety as a priority, the chamber provides complete UV protection during use. Its versatility makes it an ideal tool for production lines, R&D laboratories, and specialised applications like resin curing, 3D printing, dental applications, and medical assembly. Beyond curing, the customisable design can be configured for other functions, such as a disinfection unit, particle inspection chamber, or a UV accelerated aging chamber, making it a truly adaptable machine for your specific requirements.

If you have any questions, please contact us to discuss your specific needs.

Technical Specifications

LED Wavelength: 365nm, 385nm, 395nm, 405nm and other wavelengths upon request

Light Intensity: Up to 10,000 mW/cm²

Power: Adjustable power settings from 10% to 100%

Timer: Countdown timer settings from 0.1s to 999.9s

LED Irradiation Area: A wide range of options available to suit your application needs

Operating Life: > 20,000 hours under normal operating conditions

Controls: Integrated intuitive touch-screen controls or a separate LED controller unit

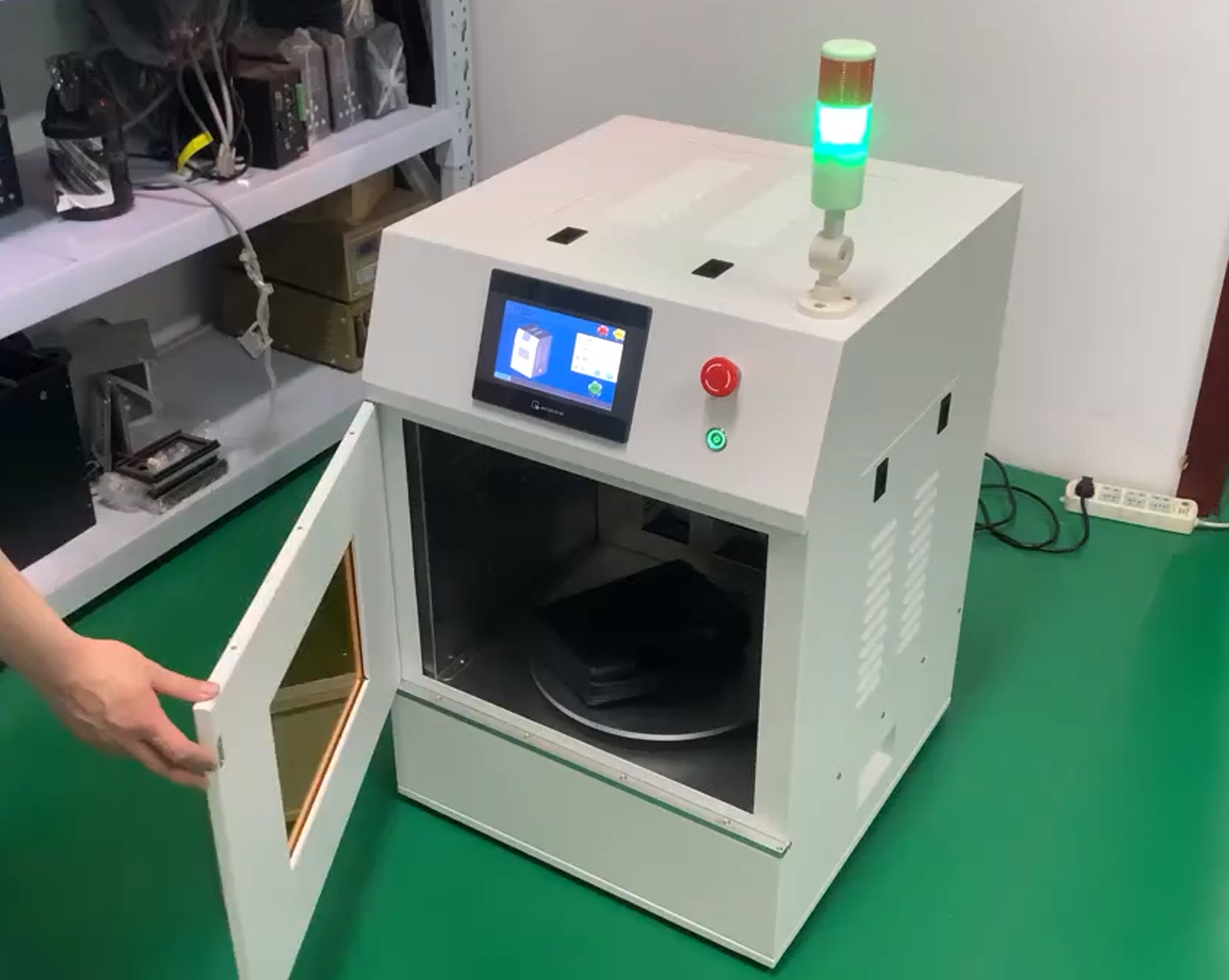

Safety Features: Complete UV-blocking enclosure, chamber door safety cut-off, traffic light beacon with alarm (optional), emergency stop switch (optional)

Operation Modes:

Continuous run at constant power setting

Timer mode at constant power setting

Multi-steps profile, up to 20 steps in 1 cycle

Chamber Size: Standard 200x200mm, can be customised

Options:

Water cooling LEDs for highest intensity output,

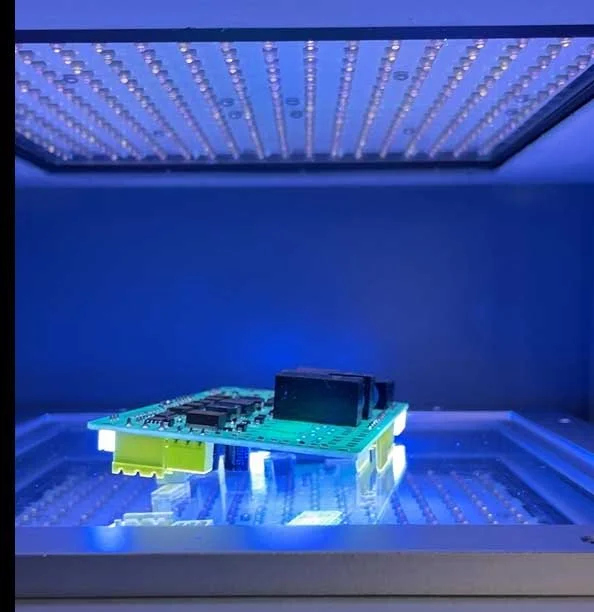

Top and bottom in-line UV curing

Inert gas environment,

Humidity controls,

Temperature-regulated environment,

Table rotation for 360° curing,

Stackable chamber

Standard UV curing chamber with touch-screen control

Stacked UV chambers to minimise footprint

UV curing chamber with rotation table

UV chamber with heating by forced convection

Top and bottom LEDs for double-sided UV curing

UV chamber with nitrogen gas purging controls, temperature controls and humidity controls

Have questions or need a demo?

We would love to help! Get in touch with our team for more information or to arrange a system demonstration.