Customised UV LED Curing Solutions

Our UV LED curing solutions are engineered for flexibility and performance, with every aspect customisable to meet your specific needs. From the size of the LED curing heads to the wavelength of the light, we provide bespoke equipment that integrates seamlessly into your production process. We specialise in creating UV LED surface light sources of any specification or size, giving you unparalleled control.

Please contact us to discuss your specific needs.

Unparalleled flexibility: We offer a vast range of customisation options for wavelength, size, and shape of our light sources to perfectly match your unique application.

High performance LED chips: Our systems are built with high-quality LED chips from Japan and Korea, ensuring high energy, uniform illumination, and exceptional stability.

Intuitive control: A user-friendly touchscreen interface allows for precise power adjustments (10%-100%) and curing durations.

Energy efficiency: Our systems are highly efficient, consuming only about one-tenth the power of traditional UV mercury lamps, leading to significant energy savings.

Customisation with Adhera

Eco-friendly: Our equipment is mercury-free and produces no ozone, making it a clean and environmentally responsible choice.

Long-lasting performance: With an average lifespan of over 20,000 hours, our light sources outlast traditional mercury lamps by a wide margin and can be switched on/off instantly without affecting longevity.

No heat stress for your products: Our UVLED sources emit a single-wavelength light without infrared radiation, preventing the substrate's surface temperature from rising by more than 5°C, making them safe for heat-sensitive materials.

Reduce footprint: Our light sources are significantly smaller and lighter than traditional UV lamps, with a customizable footprint that is, on average, 1/10th the size, allowing for easy installation in various work environments.

Large UV LED head 550 x 450mm

UV Curing Tunnel

Omni-directional UV Curing Solution

Ring Light

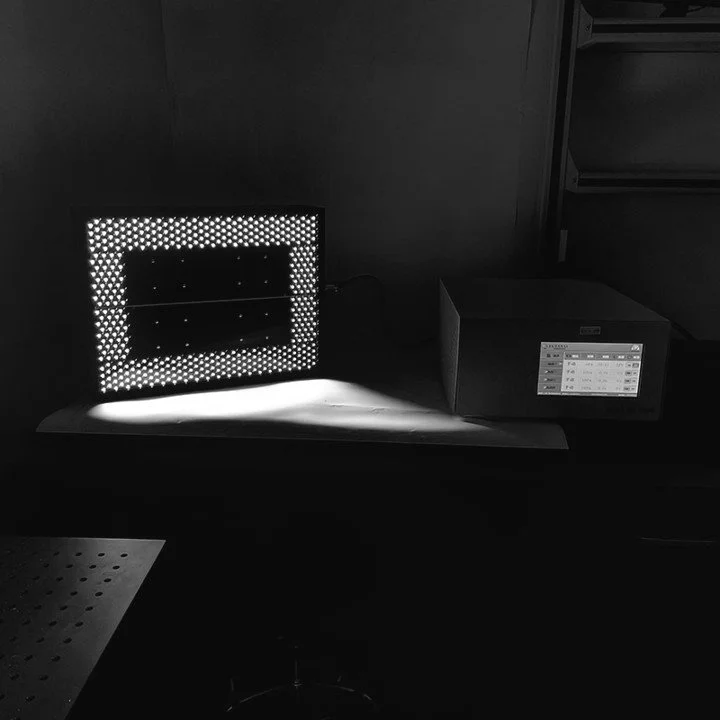

Frame-shaped light

UV Light Tower

Applications

Optics:

Curing of optical cement for lens bonding.

Curing of clear monomer resins for micro- or nano-scale lenses. These lenses are essential for advanced optical sensing and light projection in devices such as LiDAR, gesture and facial recognition systems, light carpets, heads-up displays, car headlights, heartbeat sensors, in-ear detection sensors, augmented and virtual reality devices, and many more.

Image Sensors: Curing of adhesives for camera lenses and optics used in smartphones, automotive cameras, and endoscopes.

Automotive: Curing of flame retardant coatings during EV battery manufacturing.

Plastics: Curing of UV ink and UV lacquer coatings on plastic containers.

3D Printing: Curing of resins to finalize 3D printed parts.

Display Bonding: Curing of adhesives for glass bonding on displays.

Medical Applications: Curing of adhesives for bonding cannula tips for intracutaneous needles, sealing medical catheters, and connecting plastic tubes.

Research & Development with UV light: Curing of various materials for UV-ageing tests, including assessing the resistance of paints, sunblock lotions, and perfumes against UV light, and studying the degradation of polymer materials.

Optical Communication:

Curing of adhesives for bonding waveguides, prisms, diffractive and refractive optics, and mirrors.

Curing of the protective jacket around optical fibres.

Fibre splicing and fixing.

PCBA: Curing of glob top and conformal coating in PCBs.

Smart Cards: Curing of glob top to protect chips from damage.

Solar Panel Manufacturing: Curing of encapsulation materials for photovoltaic cells.

Have questions or need a demo?

We would love to help! Get in touch with our team for more information or to arrange a system demonstration.